SINCE 1956,

OUR HERITAGE

JCM…

NEW JCM has earned a reputation for providing innovative turbo machinery solutions, unmatched expertise, and best-in-class services to the turbo machinery market place.

We offer a combination of technology and experience from the trusted names in turbo machinery solutions through our more than 50 years of servicing and reverse engineering of the best names in the turbo machinery world.

We have been providing advanced and practical technologies in aerodynamics, rotor dynamics, process solutions and metallurgy for decades.

We understand that change is essential in achieving and maintaining a competitive advantage in today’s challenging oil, gas, petrochemical and power industries.

Together with our customers, suppliers and technology partners, we continue to innovate, improve and expand our portfolios and services for the betterment of our customers.

TECHNOLOGY LEADERSHIP

NEW JCM provides leading complete turbo machinery solutions. Your applications are too important, too critical, not to have the best available technology on your side.

NEW JCM engineers have Ph.D and M.S. degrees in their fields of expertise and are active participants in the development of China’s industry standards.

- Mr Fei Chun Yin, a Professor and engineering expert in the turbo machinery sector, is a pioneer in China’s compressor industry. As the former Deputy Chairman of JCM Group, he has more than 30 years of experience in designing and manufacturing centrifugal compressors and steam turbines.

- In 1996, Mr Fei helped establish a technical collaboration with MHI Japan to design and manufacture compressors and steam turbines in China.

- In 2000, hei led a team to design China’s largest and very first 450 Kt/y PX unit MHI 7V-4 compressor.

- Mr Fei led and supervised the JCM/MHI teams in the design of 4V-9 and 4V-8S compressor with MHI technology.

- Under his leadership as chairman, New JCM won the contract to help build the world’s largest methanol project in China by supplying 16 compressors using New JCM’s proprietary technologies.

- Mr Fei is the recipient of the China Liaoning Science Improvement Prize awarded by China’s State Council.

Manufacturing and Testing Capabilities

NEW JCM employs state-of-art production techniques that minimise cycle times and costs while providing customers with the most competitive and reliable products. Our advanced manufacturing capabilities include a centre for casing machining, rotor machining and diaphragms.

NEW JCM’s state-of-the-art Schenk High Speed Dynamic Balancing machine is housed in a bunker-type vacuum chamber.

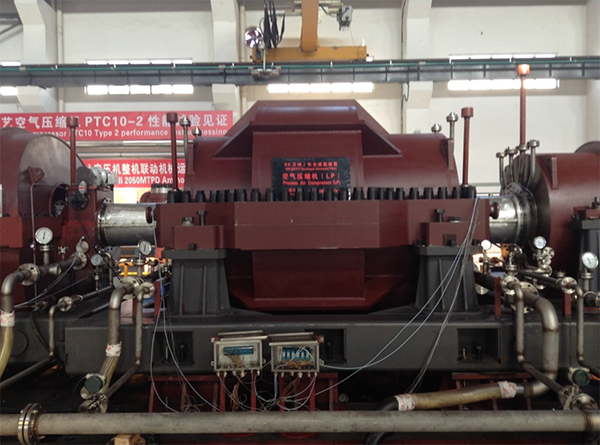

Our recently modernised and expanded facilities enable us to perform API617 mechanical integrity test and ASME PTC-10 Class II performance test on our compressors.

As the only company in China to perform STRING tests of steam turbine and compressors together, NEW JCM is capable of operating a compressor train at full load of up to 25MW. Our facilities include a range of performance testing devices, cooling towers and a central control room. In addition to rotation and performance testing of individual compressors, we also perform STRING tests in which the compressor and mechanical drive steam turbine are connected and operated at the same time.

All our products are subject to stringent testing at every stage of the design and manufacturing process where we employ state-of-the-art techniques and experienced professionals to confirm specifications and find opportunities for improvement.

NEW JCM expands

NEW JCM is planning to invest US$16 million to expand and upgrade our capabilities. In 2012, we added 12,990 square metres of new floor area that includes a new test bay that can perform the complete package testing for compressors and steam turbines. This is the only test capability available in China, giving added value to our customers in China and abroad. The new machining capacities have also enhanced our manufacturing and production capabilities.

Advanced Computational Fluid Dynamics and Aerodynamics & Enhanced Performance are one of our service offerings including the technology to design compressors and steam turbines.

CCAD® is the 3D geometry generation and quasi-3D flow analysis program for centrifugal and mixed-flow compressors, pumps and turbines.

CCAD® is used for designing the flow passages and blading for all kinds of centrifugal and mixed-flow machines. CCAD® can be used to design inlets, impellers, inducers, diffusers, crossovers, nozzles, and volutes. CCAD® includes both an integrated quasi-3D flow solver, with two-zone modelling, for near real-time fluid dynamic loading calculations and a separate optional boundary layer solver. All geometry in CCAD® is specified with Bernstein-Bezier polynomials and Non-Rational Uniform Bezier Spline (NURBS) surfaces, giving smooth, continuous surfaces ideal for both CFD analysis and machining. CCAD® also accepts geometry input from existing designs using the CADFIT feature.

Three dimensional digital CNC machining

CAS/CAM & Numerical Control Machining Capabilities

NEW JCM Assembly and Advanced Test Center for Compressors and Mechanical Drive Steam Turbine

NEW JCM has invested in Human Resources and facilities to ensure manufacturing, Quality and delivery costs are controlled. Hence improve in overall costs/values to customers.

In Collaborations with Strategic Partners to Enhance New JCM Capabilities……….

All Performance Tests and Mechanical Run String Tests will be based on API and ASME Guidelines discussed and agreed with customers, all Tests will witness and data will live display on screen and recorded.